This involved the major extension to a production facility. The facility was to be the first of a two-phase development housing new production lines. It incorporated raw materials and finished product bins, an extrusion and production plant, and plasma physics-based odour control plant.

The plant and steel frame was supplied by a Process Engineering specialist based in the Netherlands, where fabrication of the steelwork would also take place. We designed steelwork connections for the fabricator and made a number of visits to ensure coordination of this complex design, which included European steel sections for the main frame.

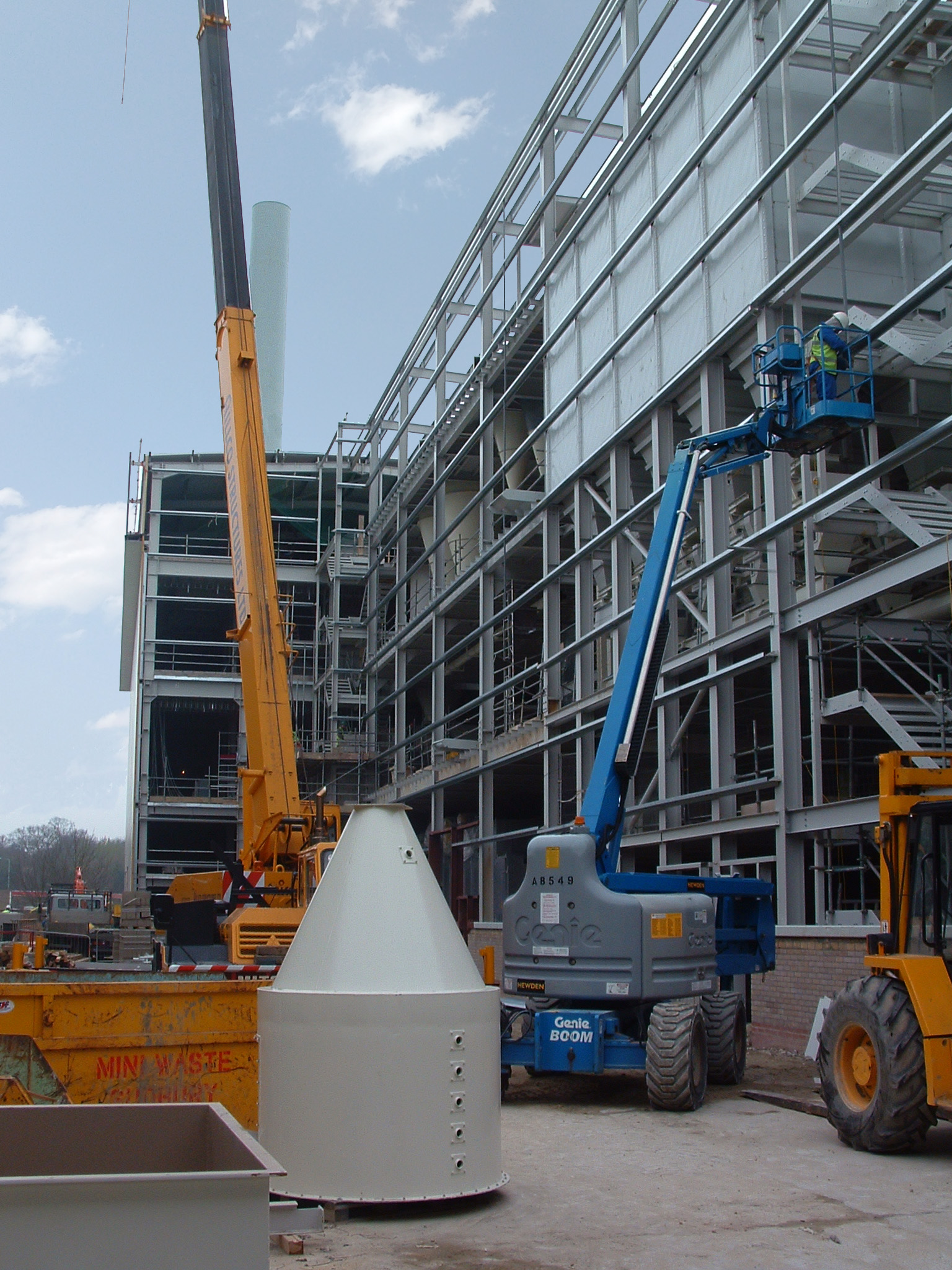

The impact on site logistics was significant; careful planning maintained our client’s operation. A tight site with limited space for construction plant and materials, and the need to divert of mains public sewers, which ran through the centre of the site, created further challenges.